Weighing and packing of carrots in sealed bags

Delivery March 2012

Product Carrots

Portion sizes 0,5-2,5 kg

Partner Gillenkirch

Capacity 60 portions/min. (30 portions per packaging machine)

Machines included

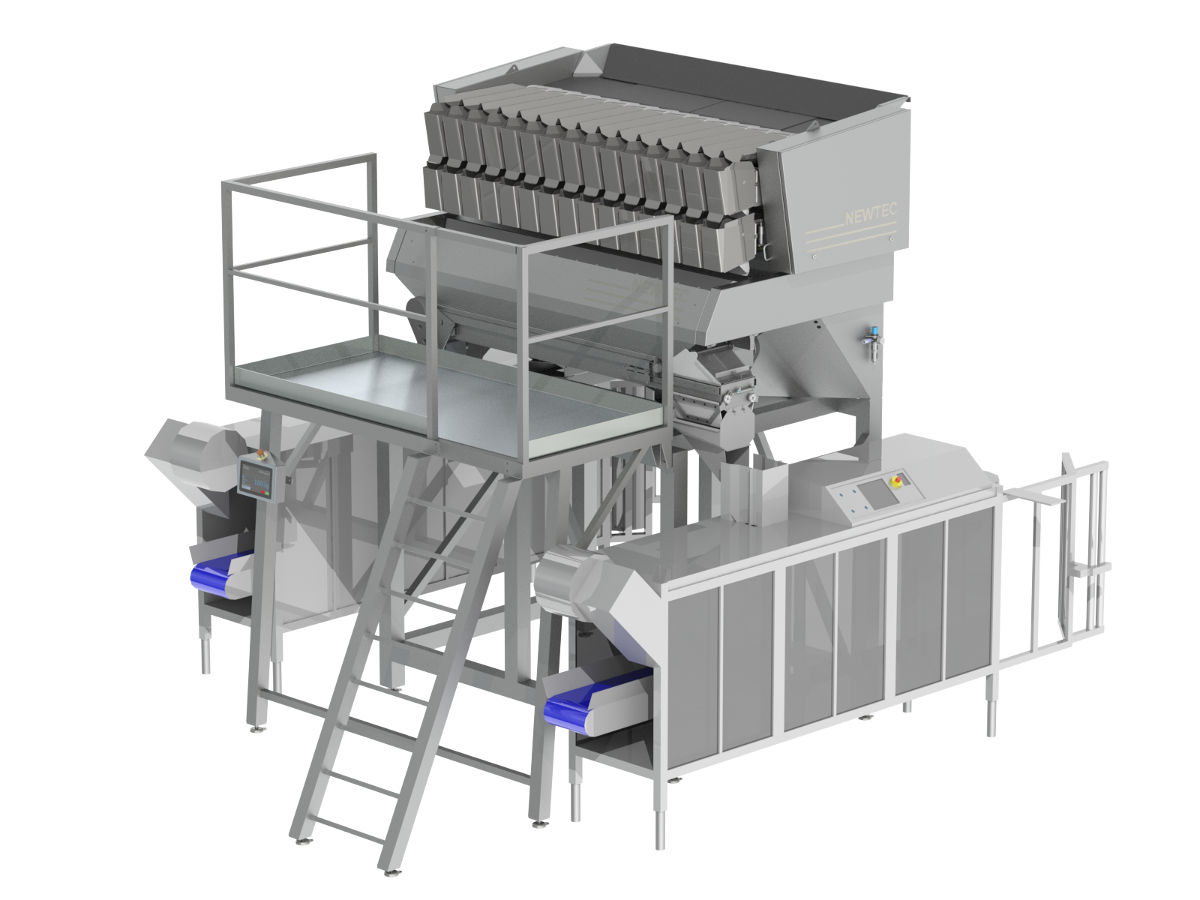

- Newtec weighing machine, model 4015B2G

- Two horizontal packaging machines, Gillenkirch, model 7000E-K

- Portion Collecting System (PCS) with four conveyors. Two for each side

- Floor frame and service platform

Challenge

Our customer wanted high capacity and a very gentle handling of their product with low drop height.

Solution

Newtec was chosen as supplier because of the very low giveaway, our weighers are known for (as low as 0.2% average overweight) and because we could ensure a gentle handling of their product with a low drop height. Most importantly, we guaranteed the required high capacity.

Our most recent combination weigher, model 4015B2G, was chosen for the solution to ensure the requested high speed and accuracy. The weigher is constructed with a new infeed system which ensures optimal distribution of products. Already in the vibration chutes before the weighing pans, the carrots are aligned in order to optimise speed.

The new model handles carrots up to 230 mm long. Detachable pans enables easy access for cleaning and service.

We based the packaging solution on two horizontal packaging machines to ensure the requested low drop height. In order to deliver a high speed solution, we designed a Portion Collecting System with four conveyors – two conveyors on each side. Our weigher and PCS were designed to simultaneously feed the two packaging machines. customised infeed hoppers for the bagging machine were designed, so only a few adjustments were needed during installation on site.

Further orders

Our solution has successfully been in operation since 2012 and as a result, our customer has ordered three more customised installations.